FAQ

The waste heat calculator provides an initial estimation of the technically usable amount of waste heat depending on a previously selected type of use. The actually usable waste heat potential can vary depending on the operational conditions. Simplifications had to be made for the calculations stored. The calculations are therefore based on common systems and their applications in practice. This also applies to the temperature and power ranges of the systems. If you enter values that are beyond these limits, you will receive a message.

If the calculator shows you that the internal use of waste heat is technically possible and economical, it is worth taking a closer look. We then recommend that you have a more detailed technical and economic evaluation carried out by an expert. Please note that investment costs are estimations based on German prices. They can vary from one country to another.

- Exhaust gas

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: As a rule, heat generators are not operated continuously in the nominal load range (exception: boilers with single-stage burners operate in on-off mode). You can estimate the partial load share in different ways, depending on the type of installation.

Modern boilers with control usually have a control panel, on which all necessary information can be read. At least they have an operating hours counter. As a first approach, you can also enter an empirical value.Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: The determined load (expressed as a percentage of the full load) in the different partial load states must be multiplied by the respective duration. All intermediate results are to be added.

Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12.5 50 70 35 25 90 22.5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: How can the waste heat be used?

Answer: In addition to service water heating and backup heating, it can also be used as process heat (e.g. drying, preheating, cleaning, washing, cooking, heat treatment, melting). Furthermore, if you have sufficient power and operating time, you can check both, the generation of cold and the generation of electricity using an ORC or steam power process. Waste heat can only be used for heating purposes during the heating period.

Note: For systems that are approved according to BImSchG, the installation of an exhaust heat exchanger may require a modification permit.Question: When does it make sense to generate electricity from waste heat in an ORC plant?

Answer: Electricity generation with an ORC system makes sense if the available waste heat cannot be used differently. The waste heat should have a minimum output of 200 kW and a minimum temperature of 110 °C and should be generated as continuously as possible. When determining the waste heat temperature, it should be noted that these may be located upstream of the measuring point, e.g. was reduced by false air supply.

Calculation of the waste heat calculator: Electricity is generated with an efficiency of approx. 8 percent (low waste heat output and temperature) to approx. 20 percent (high waste heat output and temperature).

Note: The system will incur additional maintenance and operating costs.Question: When does it make sense to generate electricity from waste heat with a steam power process?

Answer: Power generation with a steam power process makes sense if the available waste heat cannot be used otherwise and a steam system is available. The waste heat should have an output of at least 400 kW and a temperature of 180 °C and should be generated as continuously as possible. When determining the waste heat temperature, one should pay attention that it may be located upstream of the measuring point, e.g. was reduced by false air supply.

Calculation of the waste heat calculator: Electricity is generated with an efficiency of approx. 5 percent (low waste heat output and temperature) to approx. 17 percent (high waste heat output and temperature).

Note: The system incurs additional maintenance, operating and TÜV inspection costs.Question: What should be considered when producing refrigeration (room cooling) with an absorption refrigeration system?

Answer: The prerequisite is a waste heat output of at least 100 kW and exhaust air/flue gas temperatures of at least 100 to 105 °C. The cooling capacity is about 2/3 of the waste heat capacity. Absorption chillers should preferably be operated at the point of nominal load, not at partial load. A cold accumulator is therefore an integral part in order to avoid unfavourable cycling. An additional heat accumulator can be integrated between the waste heat source and the absorber. The required size depends on the time of use of the waste heat source and the heat requirement of the absorption refrigeration system.

If the heat accumulator is sufficiently large, a waste heat source with a high thermal output, that is only operated for a short time, can provide cooling with a low output for a long period of time. By designing the absorption refrigeration system for the high summer temperatures, they often achieve only 700 to 1500 full load operating hours per year.

Note: The waste heat calculator compares the investment costs (system including planning and installation) of absorption refrigeration system and compression chillers.

Tip: Set the absorption refrigeration systems for example to 50 percent of the required total cooling capacity and install a sufficiently large cold accumulator that provides additional cooling at peak load requirements. For peak load coverage, a (cheaper) compression refrigeration system can be provided, which, however, is only operated for a few hours a year.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What does the difference between available and usable waste heat mean?

Answer: The available annual amount of waste heat is determined by the waste heat output and the operating time of the plant; the share of partial load operation is also decisive. Simultaneous operation of source and sink makes a large part of the available annual waste heat available.

Note: The higher the usable annual amount of waste heat, the more economical it is to use waste heat.

Tip: If there are significant differences between the available and usable annual amount of waste heat, an alternative use of waste heat can be sensible in order to increase simultaneous operation.Question: What conditions apply to the use of waste heat from waste gas?

Answer: The following table shows the prerequisites for each waste heat usage type: Sufficient waste heat for the generation of cold or electricity is only generated when the furnace thermal output is sufficiently high.

Prerequisites per Waste Heat Utilization Type Possible Use of Waste Heat Minimum Rated Thermal Input (kW) at Low and High Temperatures Valid Temperature Range (°C) Minimum Waste Heat Output (kW) Maximum Achievable Waste Heat Output (kW) Service Water Heating 380 – 35 110 – 300 3 2,300 Heating/Heating Support 400 – 40 110 – 300 3 2,300 Process Heat 730 – 50 150 – 300 3 1,800 Absorption Refrigeration System 25,000 – 1,200 110 – 300 100 2,200 Power Generation: ORC Process 14,000 – 1,200 110 - 800 200 4,800 Power Generation: Steam Power Process 13,000 – 2,500 180 – 800 400 4,800 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

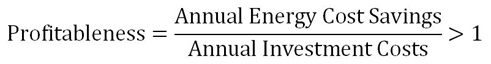

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.

Question: Can the waste heat from an ORC or steam process or the recooling heat from an absorption refrigeration system still be used?

Answer: The waste heat or recooling heat is generated at a temperature of approx. 35 to approx. 45 °C, with special systems higher temperatures of up to 75 °C are also possible. Basically, it can be used to support heating, to heat service water or, at high temperatures, to generate cold. You can estimate whether a use is economical in the "Waste water/ Cooling water" module.

- Waste water/cooling water

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: As a rule, the systems are not always operated at full load. You can estimate the partial load share in different ways, depending on the type of installation.

Modern plants with control usually have a control panel, on which all necessary information can be read. Alternatively, you can obtain indications for partial load operation by measuring the flow rate of the water volume several times (flow or volume measurement). As a first approach, you can also enter an empirical value.Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: If you cannot read the data from the system or from the aggregate papers, determine the water volume flow during typical operating conditions of the system.

Calculation: The determined water volume flow (expressed as a percentage of full load) in the different partial load conditions must be multiplied by the respective time duration. All intermediate results must be added together.Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12.5 50 70 35 25 90 22.5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: How can the waste heat be used?

Answer: The waste heat from waste water or cooling water can be used for service water heating, for heating support (radiator heating and underfloor heating), for fresh air heating in ventilation systems, for cooling and indirectly by means of a heat pump.

Note: Waste heat for heating purposes can only be used during the heating period.Question: What should be considered when producing refrigeration (room cooling) with an absorption refrigeration system?

Answer: The prerequisite is a waste heat output of at least 100 kW and water temperatures of at least 80 °C. The cooling capacity is about 2/3 of the waste heat capacity. Absorption chillers should preferably be operated at the point of nominal load , not at partial load. A cold accumulator is therefore an integral part in order to avoid unfavourable cycling. An additional heat accumulator can be integrated between the waste heat source and the absorber. The required size depends on the time of use of the waste heat source and the heat requirement of the absorption refrigeration system. If the heat accumulator is sufficiently large, a waste heat source with a high thermal output, that is only operated for a short time, can provide cooling with a low output for a long period of time. By designing the absorption refrigeration system for the high summer temperatures, they often achieve only 700 to 1500 full load operating hours per year.

Note: The waste heat calculator compares the investment costs (system including planning and installation) of absorption refrigeration system and compression chillers.

Tip: Set the absorption refrigeration systems for example to 50 percent of the required total cooling capacity and install a sufficiently large cold accumulator that provides additional cooling at peak load requirements. For peak load coverage, a (cheaper) compression refrigeration system can be provided, which, however, is only operated for a few hours a year.Question: What has to be considered when using waste heat with a heat pump?

Answer: : A heat pump increases the temperature of the waste heat with a low temperature level (e.g. 30 °C) to the flow temperature of a heating system (approx. 55 - 75 °C). As the temperature difference between the waste heat source and the heating system (heat sink) increases, however, the heating output and efficiency of the heat pump decrease.

Note: The heat pump requires additional electricity: You can approximately estimate electricity costs of 0.06 € per kWh of annual waste heat output. These costs shall be deducted from the annual fuel cost saving.Question: What influence does the simultaneous operation of waste heat source and heat sink have?

Answer: Waste heat supply and heat demand must coincide as closely as possible so that a high proportion of the available waste heat can be used.

Tip: If waste heat recovery is uneconomical, it may be possible to increase the simultaneous operation and thus the usable annual waste heat quantity.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What does the difference between available and usable waste heat mean?

Answer: The available annual amount of waste heat is determined by the waste heat output and the operating time of the plant; the share of partial load operation is also decisive. Simultaneous operation of source and sink makes a large part of the available annual waste heat available.

Note: The higher the usable annual amount of waste heat, the more economical it is to use waste heat.

Tip: If there are significant differences between the available and usable annual amount of waste heat, an alternative use of waste heat can be sensible in order to increase simultaneous operation.Question: What conditions are applicable for using waste heat from waste water?

Answer: The following table shows the prerequisites for each waste heat usage type:

Prerequisites per Waste Heat Utilization Type Possible Use of Waste Heat Valid Temperature Range (°C) Minimum Waste Heat Output (kW) Maximum Achievable Waste Heat Output (kW) Service Water Heating 30 – 95 3 2.000 Convector/Radiator Heating 60 – 95 3 2,500 Floor Heating System 40 – 95 3 2,500 Air Heating 30 – 95 3 1,500 Heat Pump 15 – 40 3 400 Absorption Refrigeration System 80 - 95 100 2,500 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

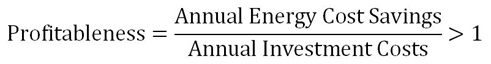

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.

- Cooling system

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: As a rule, the systems are not always operated at full load. You can estimate the partial load share in different ways, depending on the type of installation. Modern plants with control usually have a control panel, on which all necessary information can be read. Alternatively, you can obtain reference points for partial load operation with multiple current measurements over a period that is as representative as possible. As a first approach, you can also enter an empirical value.

Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: If you cannot read the data of controlled refrigeration compressors from the system, refer to the system documentation for the corresponding refrigeration capacity during typical operating conditions.

Calculation: The determined load (expressed as a percentage of the full load) in the different partial load states must be multiplied by the respective time duration. All intermediate results must be added together.Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12.5 50 70 35 25 90 22.5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: How can the waste heat be used?

Answer: The best solution is a simultaneous cooling and heating requirement. Different load profiles of waste heat source and heat sink can partly be compensated by a heat accumulator. The waste heat from a refrigeration system can be used to heat service water, to support heating and to heat fresh air in ventilation systems.

Note: Waste heat can only be used for backup heating during the heating period.Question: What influence does the simultaneous operation of waste heat source and heat sink have?

Answer: Waste heat supply and heat demand must coincide as closely as possible so that a high proportion of the available waste heat can be used.

Tip: If waste heat recovery is uneconomical, it may be possible to increase the simultaneous operation and thus the usable annual waste heat quantity.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What does the difference between available and usable waste heat mean?

Answer: The available annual amount of waste heat is determined by the waste heat output and the operating time of the plant; the share of partial load operation is also decisive. Simultaneous operation of source and sink makes a large part of the available annual waste heat available.

Note: The higher the usable annual amount of waste heat, the more economical it is to use waste heat.

Tip: If there are significant differences between the available and usable annual amount of waste heat, an alternative use of waste heat can be sensible in order to increase simultaneous operation.Question: What conditions apply to the waste heat recovery of a refrigeration plant?

Answer: The following table shows the prerequisites for each waste heat usage type:

Prerequisites per Waste Heat Utilization Type Possible Use of Waste Heat El. Minimum Power (kW) Temperature- range (°C) Minimum Waste Heat output (kW) Maximum Achievable Waste Heat Output (kW) Service Water Heating 3 30 – 50 3 2,000 Floor Heating System 3 40 – 50 3 2,000 Air Heating 3 30 – 50 3 2,000 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

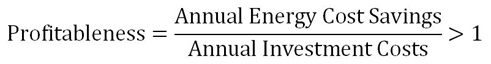

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.

- Process exhaust air

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: As a rule, exhaust air systems are not constantly operated in the nominal load range (exception: unregulated fans). You can estimate the partial load share in different ways, depending on the type of installation.

Modern systems with control usually have a control panel, on which all necessary information can be read. At least they have an operating hours counter. By measuring the current several times over a period that is as representative as possible, you obtain indications for partial load operation. Alternatively, you can determine the air volume or the air flow with a flow or volume measurement. As a first approach, you can also enter an empirical value.Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: If you cannot read the data of controlled fans from the system, determine the speed during typical operating states. In the data sheet of the system you will find the corresponding air volume flow. Alternatively, the flow or volume of an air flow can be measured at different partial load conditions.

Calculation: The determined air volume flow (expressed as a percentage of the nominal volume flow) in the different partial load conditions must be multiplied by the respective duration. All intermediate results must be added together.Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12.5 50 70 35 25 90 22.5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: How can the waste heat be used?

Answer: In addition to service water heating, heating support and fresh air heating of a ventilation system, it can also be used as process heat (e.g. drying, preheating, cleaning, washing, cooking, heat treatment, melting). Furthermore, if you have sufficient power and operating time, you can check both, the generation of cold and electricity using an ORC or steam power process.

Note: The use of waste heat for heating purposes is only possible during the heating period.Question: When does it make sense to generate electricity from waste heat in an ORC plant?

Answer: Electricity generation with an ORC system makes sense if the available waste heat cannot be used differently. The waste heat should have a minimum output of 200 kW and a minimum temperature of 110° °C and should be generated as continuously as possible. When determining the waste heat temperature, it should be noted that these may be located upstream of the measuring point, e.g. was reduced by false air supply.

Calculation of the waste heat calculator: Electricity is generated with an efficiency of approx. 8 percent (low waste heat output and temperature) to approx. 19 percent (high waste heat output and temperature).

Note:The system will incur additional maintenance and operating costs.Question: When does it make sense to generate electricity from waste heat with a steam power process?

Answer: Power generation with a steam power process makes sense if the available waste heat cannot be used otherwise and a steam system is available. The waste heat should have an output of at least 400 kW and a temperature of 180 °C and should be generated as continuously as possible. When determining the waste heat temperature, one should pay attention that it may be located upstream of the measuring point, e.g. was reduced by false air supply.

Calculation of the waste heat calculator: Electricity is generated with an efficiency of approx. 5 percent (low waste heat output and temperature) to approx. 16 percent (high waste heat output and temperature).

Note: The system incurs additional maintenance, operating and TÜV inspection costs.Question: What should be considered when producing refrigeration (room cooling) with an absorption refrigeration system?

Answer: The prerequisite is a waste heat output of at least 100 kW and exhaust air/flue gas temperatures of at least 100 to 105 °C. The cooling capacity is about 2/3 of the waste heat capacity. Absorption chillers should preferably be operated at the point of nominal load, not at partial load. A cold accumulator is therefore an integral part in order to avoid unfavourable cycling. An additional heat accumulator can be integrated between the waste heat source and the absorber. The required size depends on the time of use of the waste heat source and the heat requirement of the absorption refrigeration system.

If the heat accumulator is sufficiently large, a waste heat source with a high thermal output, that is only operated for a short time, can provide cooling with a low output for a long period of time. By designing the absorption refrigeration system for the high summer temperatures, they often achieve only 700 to 1500 full load operating hours per year.

Note: The waste heat calculator compares the investment costs (system including planning and installation) of absorption refrigeration system and compression chillers.

Tip: Set the absorption refrigeration systems for example to 50 percent of the required total cooling capacity and install a sufficiently large cold accumulator that provides additional cooling at peak load requirements. For peak load coverage, a (cheaper) compression refrigeration system can be provided, which, however, is only operated for a few hours a year.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What does the difference between available and usable waste heat mean?

Answer: The available annual amount of waste heat is determined by the waste heat output and the operating time of the plant; the share of partial load operation is also decisive. Simultaneous operation of source and sink makes a large part of the available annual waste heat available.

Note: The higher the usable annual amount of waste heat, the more economical it is to use waste heat.

Tip: If there are significant differences between the available and usable annual amount of waste heat, an alternative use of waste heat can be sensible in order to increase simultaneous operation.Question: What conditions apply to the waste heat recovery of process exhaust air?

Answer: The following table shows the prerequisites for each waste heat usage type: Sufficient waste heat for the generation of cold or electricity is only generated when the exhaust air volume flow is sufficiently high.

Prerequisites Per Waste Heat Utilization Type Possible Use of Waste Heat Minimum Exhaust Air Volume Flow (m³/h) at Low and high Temperatures Valid Temperature Range (°C) Minimum Waste Heat output (kW) Maximum Achievable Waste Heat Output (kW) Service Water Heating 1,200 – 130 55 – 250 5 3,700 Heating/Heating Support 1,700 – 140 65 – 250 5 3,400 Fresh Air Heating 1,700 – 80 45 – 250 5 3,700 Process Heat 46,300 – 1,400 145 – 250 35 2,300 Absorption Refrigeration System 42,000 – 3,600 115 – 250 100 2,500 Power Generation: ORC Process 20,000 – 6,100 110 – 500 200 4,800 Power Generation: Steam Power Process 26,000 – 15,000 180 – 500 400 4,800 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

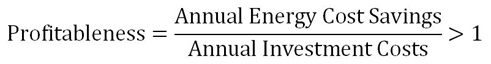

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.

Question: Can the waste heat from an ORC or steam process or the recooling heat from an absorption refrigeration system still be used?

Answer: The waste heat or recooling heat is generated at a temperature of approx. 35 to approx. 45 °C, with special systems higher temperatures of up to 75 °C are also possible. Basically, it can be used to support heating, to heat service water or, at high temperatures, to generate cold. You can estimate whether a use is economical in the "Waste water/ Cooling water" module.

- Ventilation and air-conditioning systems

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: Adjustable systems are usually not operated at full load all the time. You can estimate the partial load share in different ways, depending on the type of installation.

Modern systems with control usually have a control panel, on which all necessary information can be read. Most systems have at least one operating hours counter. Alternatively, you can obtain reference points for partial load operation with multiple current measurements over a period that is as representative as possible. The air volume or the air flow can be determined with a flow or volume measurement. As a first approximation, you can also enter an empirical value.Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: If you cannot read the data of controlled fans from the system, determine the speed during typical operating states. In the data sheet of the system you will find the corresponding air volume flow.

Calculation: The determined air volume flow (expressed as a percentage of the nominal volume flow) in the different partial load conditions must be multiplied by the respective duration. All intermediate results must be added.Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12,5 50 70 35 25 90 22,5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: How is the waste heat used?

Answer: In ventilation and air conditioning (HVAC) systems, the waste heat is used for heat recovery.

Question: Which heat exchangers are used to transfer the heat?

Answer: You can choose between a plate heat exchanger, a closed circuit system or a rotary heat exchanger for heat transfer. The rotary heat exchanger also transfers latent heat, but its costs are significantly higher. Which type of heat exchanger is sensible and economical must be decided on a case-by-case basis.

Note: The use of waste heat for heating purposes is only possible during the heating period.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What conditions apply to the waste heat recovery of a ventilation and air-conditioning system?

Answer: The following table shows the prerequisites for the most important heat exchangers:

Requirements for the Most Important Heat Exchangers Heat Exchanger Minimum Volume Flow (m³/h) Temperature (°C) Minimum Heat Output (kW) Maximum Achievable Waste Heat Output (kW) Plate Heat Exchanger 900 28 2 180 Circuit Connection System 1,300 28 5 330 Rotary Heat Exchanger 1,600 28 5 260 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.

- Compressed air

-

Input assistance

Question: How can the share of partial load operation be determined?

Answer: Compressed air compressors are generally not operated continuously at nominal load, with the exception of load idle compressors. You can estimate the partial load share in different ways, depending on the type of installation.

Modern systems with control usually have a control panel, on which all necessary information can be read. Older systems have at least one operating hours counter. Alternatively, you can obtain reference points for partial load operation with multiple current measurements over a period that is as representative as possible. As a first approximation, you can also enter an empirical value.Question: How can the average output of multi-stage or modulating boilers in partial load operation be determined?

Answer: If you cannot read the data of controlled fans from the system, determine the speed during typical operating states. In the data sheet of the system you will find the corresponding power consumption at these operating states.

Calculation: The determined load (expressed as a percentage of the full load) in the different partial load states must be multiplied by the respective time duration. All intermediate results must be added.Sample Calculation Duration in % Partial Load Height in % Percentage of Partial Load (%) = Duration x Height of Partial Load 25 50 12,5 50 70 35 25 90 22,5 Average partial load: 70 -> The average partial load is 70 % of the nominal load.

Question: Which use of waste heat can be considered?

Answer: The waste heat from air-cooled compressors can be used to heat adjacent rooms via air ducts and overflow openings. The waste heat from water-cooled compressors allows domestic hot water heating, heating backup and fresh air heating.

Note: The use of waste heat for heating purposes is only possible during the heating period.Question: What influence does the simultaneous operation of waste heat source and heat sink have?

Answer: Waste heat supply and heat demand must coincide as closely as possible so that a high proportion of the available waste heat can be used.

Tip: If waste heat recovery is uneconomical, it may be possible to increase the simultaneous operation and thus the usable annual waste heat quantity.Question: What role do the cost estimates play in economic efficiency?

Answer: High energy cost savings (energy savings x energy price) and low capital costs (interest rate) and as long a duration as possible promote the profitability of an investment.

According to VDI Guideline 2067, a useful life (depreciation period) of 15 years is assumed for the energy infrastructure. However, the energy plants can be operated for 20 and more years.

Tip: Choose a payback period that is not too short so that the investment can become economical.Results

Question: Can the entire waste heat output be used?

Answer: If the heat output of the waste heat source and the waste heat utilisation coincide, the entire waste heat output can be used. If the heat requirement of the utilisation plant is lower, only part of the waste heat output is used - this also reduces the investment in the plant and thus increases the economic efficiency of waste heat utilisation. To calculate the actually required waste heat output, reduce the data of the waste heat source in the input form until the required smaller waste heat output is achieved.

Tip: Do not design the waste heat recovery system too large in order to increase its economic efficiency.

Also see: What do full load hours have to do with the economic efficiency of waste heat recovery systems?Question: What does the difference between available and usable waste heat mean?

Answer: The available annual amount of waste heat is determined by the waste heat output and the operating time of the plant; the share of partial load operation is also decisive. Simultaneous operation of source and sink makes a large part of the available annual waste heat available.

Note: The higher the usable annual amount of waste heat, the more economical it is to use waste heat.

Tip: If there are significant differences between the available and usable annual amount of waste heat, an alternative use of waste heat can be sensible in order to increase simultaneous operation.Question: What conditions apply to the waste heat recovery of a compressor?

Answer: I The following table shows the prerequisites for each waste heat usage type:

Prerequisites per Waste Heat Utilization Type Compressor Selection Possible Use of Waste heat Minimum Waste Weat Output (kW) Temperature (°C) Maximum Achievable Waste Heat Output (kW) Water-Cooled Compressor Service water heating 3 70 360 Water-Cooled Compressor Heating 3 70 360 Water-Cooled Compressor Fresh air heating (ventilation) 3 70 360 Air-Cooled Compressor Heating via air ducts 3 80 360 Question: How did the statements on profitability come about?

Answer: The heat recovery system is viewed. The installations between the heat exchanger and the heat recovery system are not taken into account. The real investment costs can deviate from the values stored in the waste heat calculator by +/- 20 percent. This is clearly illustrated by the classification of investments as:

Expected to be profitable Possibly profitable Expected not to be profitable Tip: Increase the simultaneous operation and thus the usable annual waste heat quantity.

Question: When is it economical to use waste heat?

Answer: An investment is economical if the annual energy cost savings are greater than the annual investment costs.

Question: What are the economically justifiable investment costs?

Answer: They are calculated from the annual energy cost savings and the annuity factor as follows:

The annuity factor results from the amortization period (period under consideration) and the capital costs (interest per year).

Question: What do full load hours have to do with the economic efficiency of waste heat recovery systems?

Answer: In order for the investment in waste heat utilisation to be worthwhile by saving energy, the plant must be in operation annually for a minimum period. This is indicated in full load operating hours. Full load hours consist of the actual operation at full load and the partial load hours converted to full load.

Note: A non-economic waste heat utilisation can usually be operated economically by increasing the full load hours.

Tip: Do not design the waste heat recovery system too large and thus increase its economic efficiency.Excursus: Check the profitability of a smaller waste heat recovery system. Since the waste heat calculator assumes that the total output of the waste heat source will be used, you must change two details about the waste heat source in the input form.

- If you reduce the plant output in a second calculation, the waste heat output will be reduced accordingly (result page).

- You can simulate the better capacity utilization of a smaller system by also setting the partial load share to zero or increasing the average partial load capacity to 100%.

- This increased the hours of full load use and thus also the economic efficiency as a rule.

As a result, you use a similar waste heat quantity as originally calculated. At the same time, this heat recovery system with lower output is cheaper.